Location

Izmir, Turkey

Mon - Fri 9:00 - 6:00

Izmir, Turkey

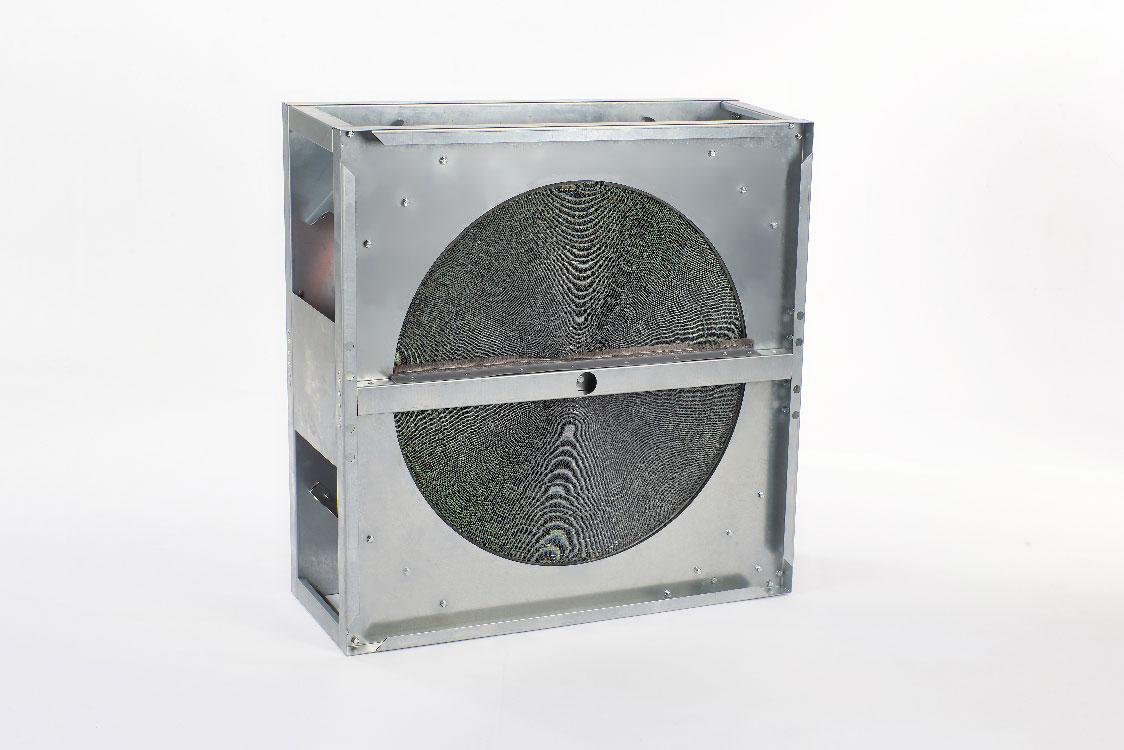

Rotary heat exchangers are the most efficient heat recovery technology that provides air-to-air heat recovery. It has a cylindrical structure and rotates in a specially made case thanks to its equipment. The heat exchanger made of aluminum foil has numerous small channels through which air flows. While the heat exchanger is rotating, fresh air enters from one part and the polluted air inside comes out from the other part. During this air exchange, fresh air and polluted air don’t mix.

The rotary heat exchanger rotates at a slow speed between the hot and cold air flow without stopping. During its rotate, it transfers the heat transferred to the channels from the hot air flow coming out and the heat accumulated on it to the cold air flow entering the room. The passage of cold air through the channels where the hot air transfers heat, together with the rotation of the rotor, allows the cold air to warm up and obtains higher efficiency results than normal heat exchangers. In this way, the rotary heat exchanger can provide efficiency up to 85%. Aluminum is ideal for this process due to its high thermal conductivity.

The rotary heat recovery exchanger is delivered in a galvanized steel case with an electric motor as standard. Soft haired sealing brushes are used to prevent air leakage between the case and the heat exchanger. These specially produced brushes are not only reliable in sealing, but also long-lasting. The electric motor is connected to the wheel with a belt-pulley system and rotates the wheel at 10-12 rpm as standard. Rotary heat exchangers are also capable of self-cleaning through covers called the cleaning sector.

As in the figure above, it can be placed inside the devices as desired, regardless of the placement of the fans. In this case, the only difference is whether the cleaning sector, which is used to clean the particles that may occur in the heat exchanger, can be used or not. According to the placement of the fans, the size and size of the cleaning sector is determined at the design stage and the buyer is informed.

As shown in the figure above, the heat exchanger can be placed inside the device to be used in various ways. The motor can be placed in the most suitable position for the device during the design phase. Rotation direction can be changed as desired.

Frame width and frame height values are designed according to demand. Frame depth and rotor depth values are fixed. The case depth value can be specially designed if it meets certain conditions. There are 200 mm and 250 mm options for rotor depth. Rotor 200 mm-2500 mm çap değerleri arasında üretilebilmektedir. The rotor can be produced between 200 m m and 2500 mm diameter values.