Location

Izmir, Turkey

Mon - Fri 9:00 - 6:00

Izmir, Turkey

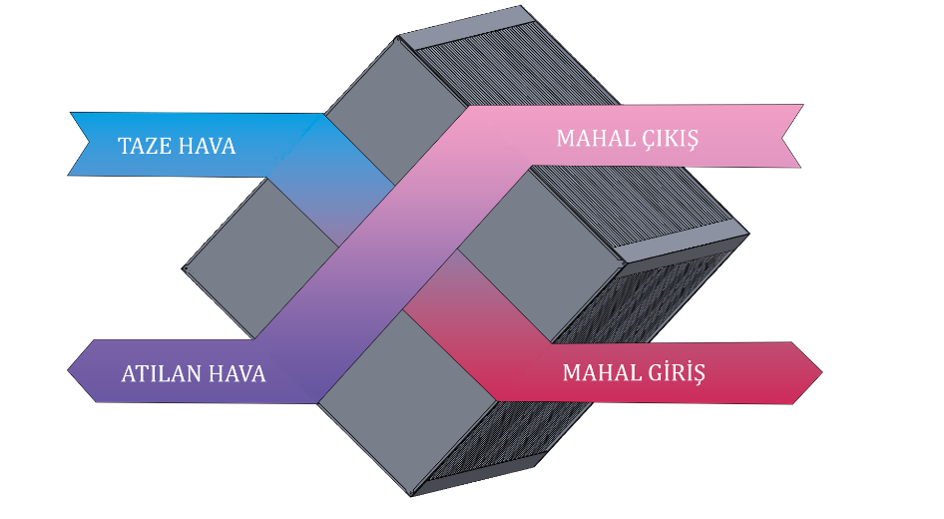

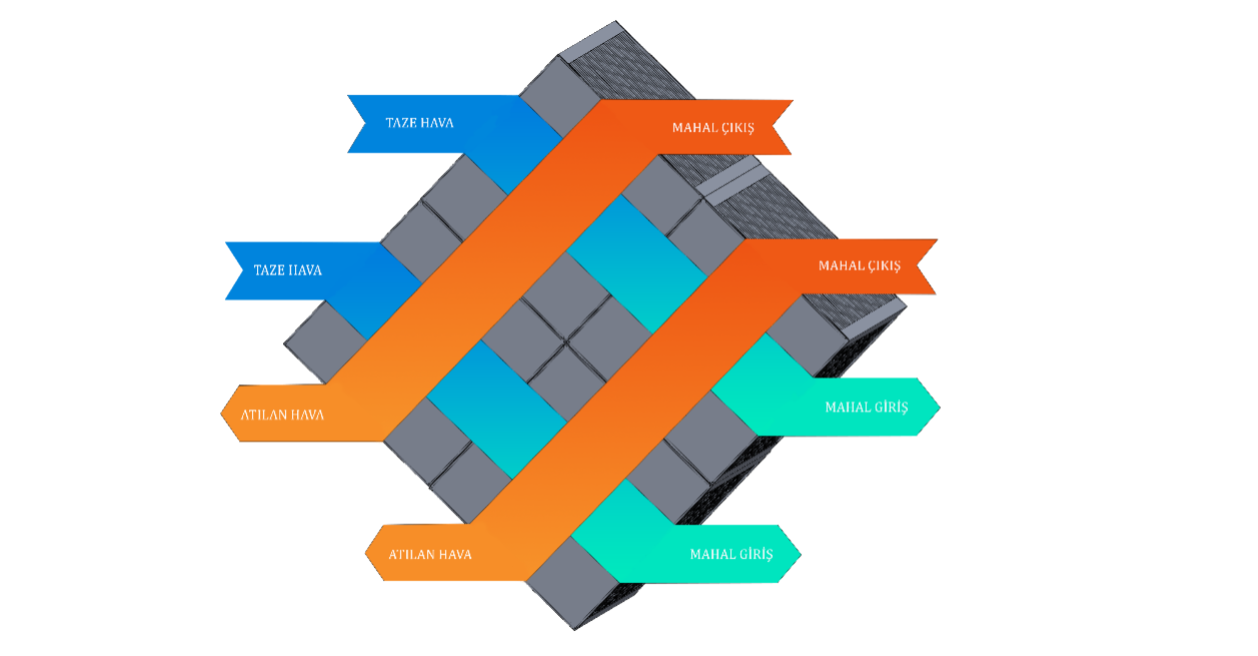

Crossflow heat exchangers are circuit elements that provide heat transfer from one to the other without mixing two air with a temperature difference between them. In this respect, it saves a lot of energy.

They do not allow polluted air to pollute the fresh air. The polluted air carrying energy and the clean air currents to which the energy will be transferred (the side that transfers energy changes according to the climatic conditions) do not come into direct contact with each other and operate independently in two separate circuits of the heat exchanger.

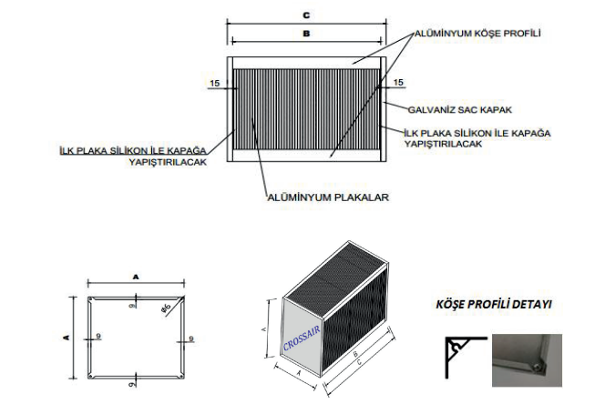

Aluminum foils, which are the main material of production, separate the two air from each other. Sealing material is used to prevent air leakage between the foils and the frames. It pours as a fluid and solidifies into a structure that will not separate and prevent leakage.

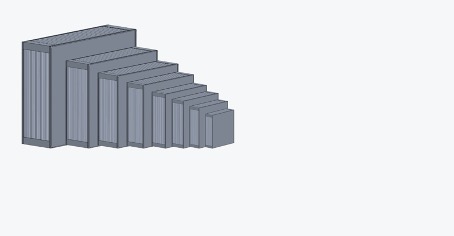

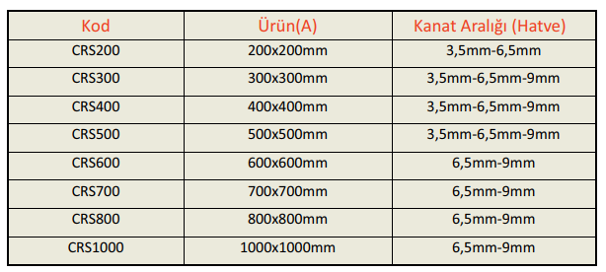

The required air flow, the desired efficiency and the pressure losses set as the limit are the main factors affecting the dimensions of the heat exchangers. In addition, the heat exchangers must be in accordance with the dimensions of the devices they will be placed in, designed by the air handling unit manufacturers. In order to meet these conditions, heat exchangers are specially produced for different projects of different customers.

Crossflow Heat Exchangers, which can be mounted inside air handling units, on Ventilation Ducts, Industrial facilities, current buildings, shopping malls, offices, hotels and hospitals, restaurants, schools, sports facilities, theaters, operas, movie theaters, swimming pools, libraries, etc. It can be applied in all kinds of comfort ventilation.

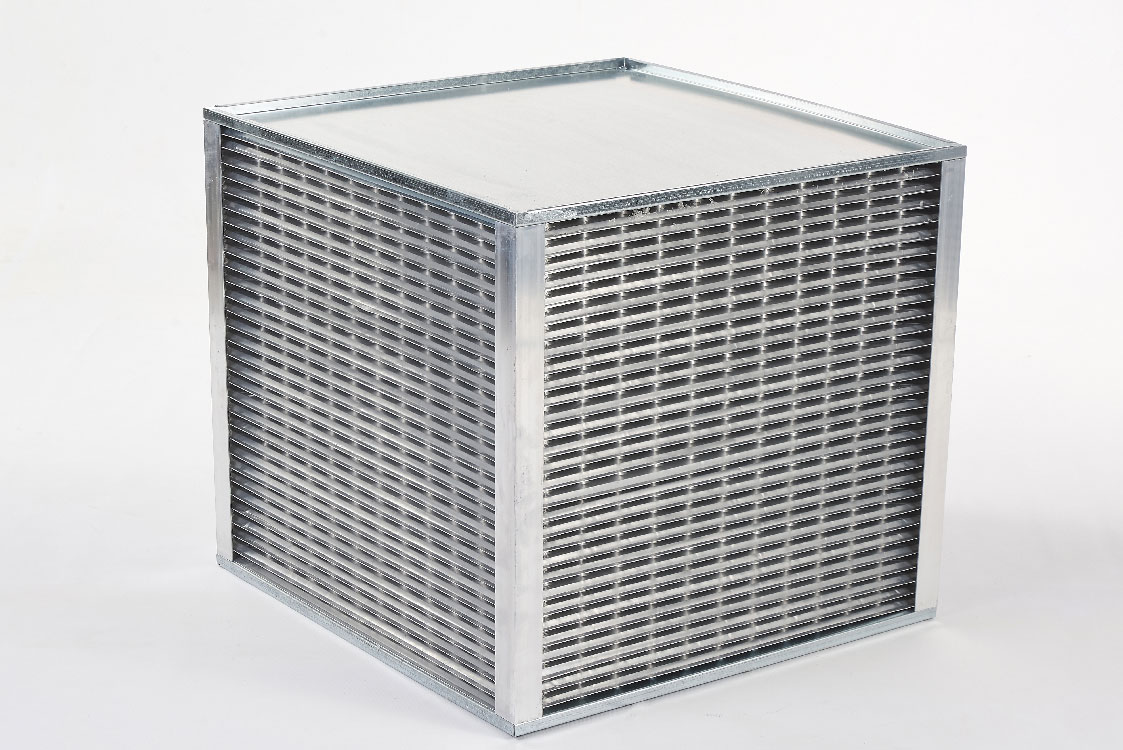

In heat exchanger production, the plates are made of aluminum and the covers are made of galvanized material. Aluminum special profiles are used in the frames. Sealing material is poured between the plates and the frames.

Heat exchangers can be used in multiple and different ways, alone or in an application.